Glass is an essential material in our daily lives, from the windows in our homes to the screens on our devices. When it comes to fire safety, many wonder about the flammability and heat resistance of glass. This comprehensive guide delves into the properties of glass, its interaction with fire, and the various types of fire-resistant glass available for enhanced safety.

The Nature of Traditional Glass

Glass is a solid material composed primarily of silicon dioxide (silica). Its creation involves melting sand and other minerals at incredibly high temperatures, then rapidly cooling the molten mixture to prevent crystallisation. This process results in a transparent, hard, and brittle material with a wide range of applications.

The basic composition of glass includes:

- Silica (SiO2): 70-74%

- Sodium oxide (Na2O): 12-16%

- Calcium oxide (CaO): 5-11%

- Other oxides: 1-6%

Additionally, glass can be affected by high concentrations of fluorine compounds, which can alter its properties. This composition can vary depending on the specific type of glass and its intended use, causing it to react differently under various conditions.

Factors Affecting Glass Flammability

While glass is generally non-flammable, several factors can influence its behaviour when exposed to fire. One of the primary factors is its chemical composition. The presence of certain additives, such as boron or silicon, can significantly affect the flammability of glass. For instance, borosilicate glass, which contains boron, is known for its high resistance to thermal shock and lower flammability compared to traditional glass.

Another critical factor is the temperature at which glass begins to decompose and combust. This temperature can vary widely depending on the glass’s chemical composition and structure. Some types of glass may start to decompose at temperatures as low as 500°C (932°F), while others may withstand much higher temperatures before showing any signs of decomposition.

The surface area of the glass also plays a crucial role in its flammability. A larger surface area can increase the risk of the glass catching fire, as it provides more opportunities for the glass to react with oxygen. Additionally, the presence of high concentrations of elemental fluorine can increase the flammability of glass. Elemental fluorine can react with the silicon in the glass to form a strong Si-F bond, which can alter the glass’s properties and make it more susceptible to catching fire.

Is Glass Flammable?

In the short answer, glass is not considered a flammable material. Here’s why:

- Glass does not ignite or catch fire when exposed to a flame.

- It does not sustain combustion or continue burning. Glass has already reached a state similar to burn ash, meaning it cannot burn further.

- Glass does not release heat or combustion products during exposure to fire.

The reason for this lies in the chemical composition of glass. As mentioned earlier, glass is primarily composed of silicon dioxide, which has already undergone a burning process during its formation. This means that glass cannot burn any further, making it inherently non-flammable.

While glass itself does not burn, certain conditions, such as high concentrations of fluorine, can lead to glass burns.

Glass Melting

Although glass doesn’t burn, it can soften and eventually melt when exposed to extremely high temperatures. Exposure to high heat can cause glass to soften and eventually melt, compromising its structural integrity. The softening point of glass is generally around 1,004°F (540°C), while its melting point is approximately 2,552°F (1,400°C).

During a fire, glass windows or doors may begin to soften and deform long before reaching these temperatures, compromising their structural integrity and ability to contain the fire.

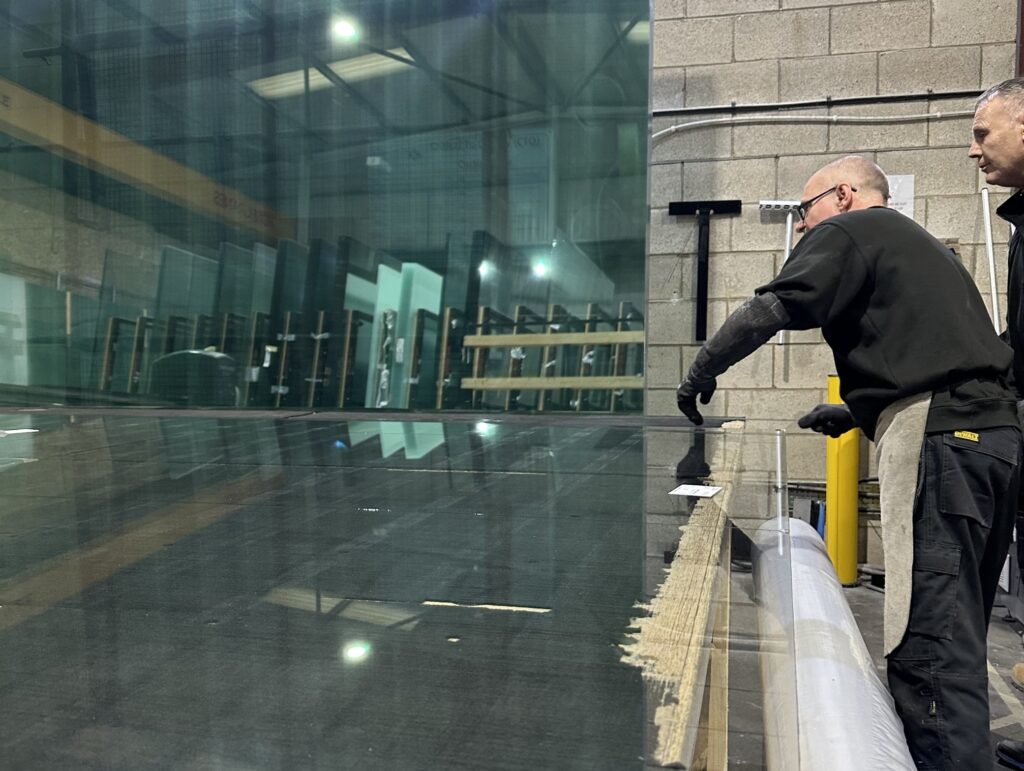

Fire-Resistant Glass Solutions

To address the limitations of standard glass in fire situations, various types of fire-resistant glass have been developed. These specialised glass products are designed to withstand high temperatures and maintain their integrity for extended periods during a fire. Fire-resistant glass is designed to withstand conditions where traditional glass might catch fire.

Fire-resistant glass is tested and rated based on its ability to withstand fire and maintain its integrity. Common fire ratings include:

- 20 minutes

- 30 minutes

- 60 minutes

- 90 minutes

- 120 minutes

These ratings indicate how long the glass can withstand standard fire test conditions while maintaining its integrity and insulation properties.

Fire-resistant glass is used in a variety of settings where fire safety is a priority. Some of the most common applications include commercial buildings, high-rise structures, educational institutions, healthcare facilities, residential buildings, industrial facilities, and transportation hubs. These environments require enhanced fire protection to safeguard occupants and assets.

In these settings, fire-resistant glass serves multiple crucial purposes. It helps contain fire and smoke, preventing their rapid spread and providing more time for safe evacuation. It also plays a vital role in maintaining clear visibility during a fire, allowing occupants and emergency responders to navigate the space more effectively. Additionally, fire-resistant glass helps protect valuable assets by acting as a barrier against heat and flames. In addition to fire protection, fire-resistant glass also helps keep out other elements such as wind, rain, and debris. Overall, its use significantly enhances building safety, making it an essential component in modern fire protection strategies.

In conclusion, while standard glass is not flammable, it can shatter or weaken under extreme heat. That’s why at Performance Glass, we offer fire-rated glass solutions designed for applications where fire safety is essential. Our fire-resistant glass is engineered to withstand high temperatures while maintaining its structure, providing protection for up to 120 minutes and integrity for up to 260 minutes. Fully compliant with UK fire safety regulations, our fire-rated glass is available in pre-cut and made-to-order options to suit your specific project requirements. Whether for commercial, residential, or industrial use, our solutions ensure enhanced safety without compromising on quality or performance. To find out more email us today on theteam@performanceglass.co.uk.