How Does Fire-Rated Glass Work?

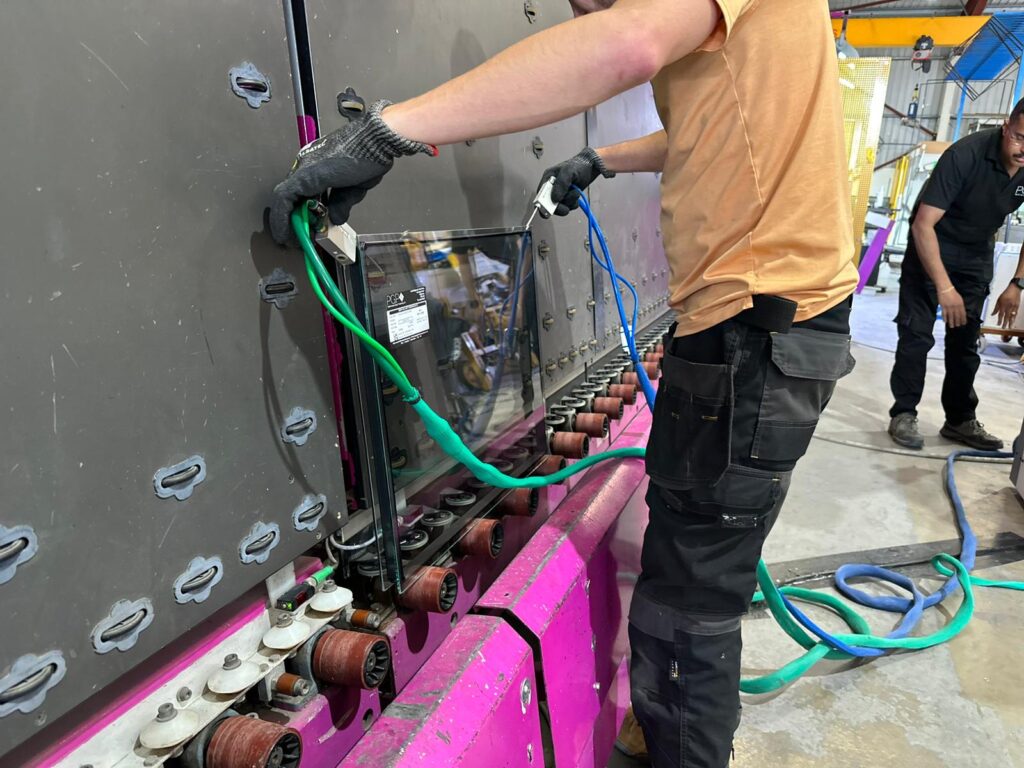

Fire safety is a critical consideration in building design and construction. Among the various safety measures implemented, fire safety glass stands out as an innovative solution that combines aesthetics with fire protection. In this comprehensive guide, we’ll explore the benefits of fire rated glass and its properties. What is Fire Rated Glass? Fire-rated glass is a specially designed type of safety glass engineered to resist the spread of fire, smoke, and radiant heat, providing critical protection in buildings during a fire emergency. Unlike ordinary glass, which can shatter at high temperatures, fire glass is made to endure extreme heat while maintaining its structural integrity for a specified period. This durability helps contain the fire and prevents it from spreading to adjacent areas, allowing for safer evacuation and minimising property damage. A key feature of fire-rated glass is its exceptional heat resistance. It can withstand high temperatures without cracking or breaking for a set duration, such as 30, 60, 90 or 120 minutes, depending on its specific rating. It also maintains its structural integrity, preventing the passage of flames and smoke to other areas of a building. Fire-rated glass is widely used in fire doors, partition walls, stairwells, and escape routes. Fire Resistant Glass Materials and Design Fire resistant glass materials are meticulously engineered to provide a robust barrier against fire, heat, and smoke. A critical component in this design is the intumescent interlayer, which is designed to expand when exposed to high temperatures, effectively repelling flames, heat, and smoke. This expansion creates a secure barrier, ensuring the integrity of the glass during a fire. The design of fire resistant glass is tailored to meet specific fire rating requirements, such as 30-minute, 60-minute, 90-minute and 120-minute ratings. These ratings indicate the duration for which the glass can withstand intense heat and flames without compromising its structural integrity. The choice of materials and the design of the glazing system are crucial in achieving these ratings. In addition to the glass itself, the overall fire rated glazing system must be carefully designed and installed to comply with fire safety codes and regulations. This involves selecting appropriate frame materials and ensuring that the glazing system is properly sealed and tested. Proper installation is essential to maximise the effectiveness of the fire resistant glass and to ensure it performs as expected in the event of a fire. Types and Ratings of Fire Rated Glazing Fire rated glass comes in various ratings, each designed to meet specific fire safety requirements. Fire Resistance Ratings Fire resistance ratings are measured in terms of time, indicating how long the glass can withstand exposure to fire without compromising its integrity. The most common fire resistance ratings for fire rated glass include: Fire Safety and Code Requirements Adhering to fire safety and code requirements is paramount in the design and installation of fire resistant glass. Fire safety codes also stipulate that fire resistant glass materials and glazing systems must be properly labeled and certified. This certification process involves rigorous testing to ensure the glass can withstand the conditions specified by the fire rating. Proper labeling and documentation are also crucial, as they provide clear information about the fire rating and compliance with safety standards. Testing and Certification Testing and certification are critical steps in the development and installation of fire resistant glass. To ensure that these materials meet specific fire rating requirements, they must undergo rigorous testing. This testing involves exposing the glazing system to intense heat and flames for a designated period. In addition to testing and certification, fire resistant glass materials and glazing systems must be properly labeled and marked to indicate their fire rating and compliance with safety standards. This includes labeling the glazing system with the fire rating, such as “30-minute fire rated,” and providing documentation to support the certification. Proper labeling ensures that building occupants and safety personnel can easily identify the fire rating and trust in the performance of the fire resistant glass in an emergency. Applications of Fire Rated Glass for Fire Safety Fire rated glass finds its applications in a wide range of settings, from commercial buildings to residential homes. Here’s some of the situations fire rated glass is used in. Fire Doors and Partitions Fire rated doors are essential in ensuring safety during a fire by preventing the spread of flames, smoke, and gases. Fully glazed fire doors provide effective fire protection while allowing natural light to flow through spaces, creating brighter and more open environments. Fire rated glass is often used in fire doors and partitions to create a barrier between different areas of a building. This allows for safe evacuation during a fire while still maintaining visual connectivity. Stairwells and Lifts Fire rated glass is commonly used in stairwells and lifts to prevent the spread of fire and smoke. It also limits heat transfer to the non-fire side, ensuring safety by maintaining a lower temperature in areas where occupants may be, thus enhancing fire safety protocols. Its transparency allows for easy navigation during emergencies. Windows Fire rated glass can be used in windows to provide fire protection while still allowing natural light to enter the building. Insulated glass units (IGUs) play a crucial role in providing both fire protection and insulation, as their multiple panes create an air vacuum or gas-filled gap that offers insulation against heat and noise. This is especially important in high-rise buildings where fire safety is a top priority. Looking for Fire Rated Glass? Fire rated glass is a crucial element in modern fire safety systems, providing a transparent barrier against the spread of flames, smoke, and heat. Whether it’s in commercial buildings, residential homes, or public spaces, here at Performance Glass we process fire rated glass that can offer protection for up to 120 minutes and integrity for up to 260 minutes. To find out more about our products or to place an order, drop us an email today on theteam@performanceglass.co.uk.

How Does Fire-Rated Glass Work? Read More »